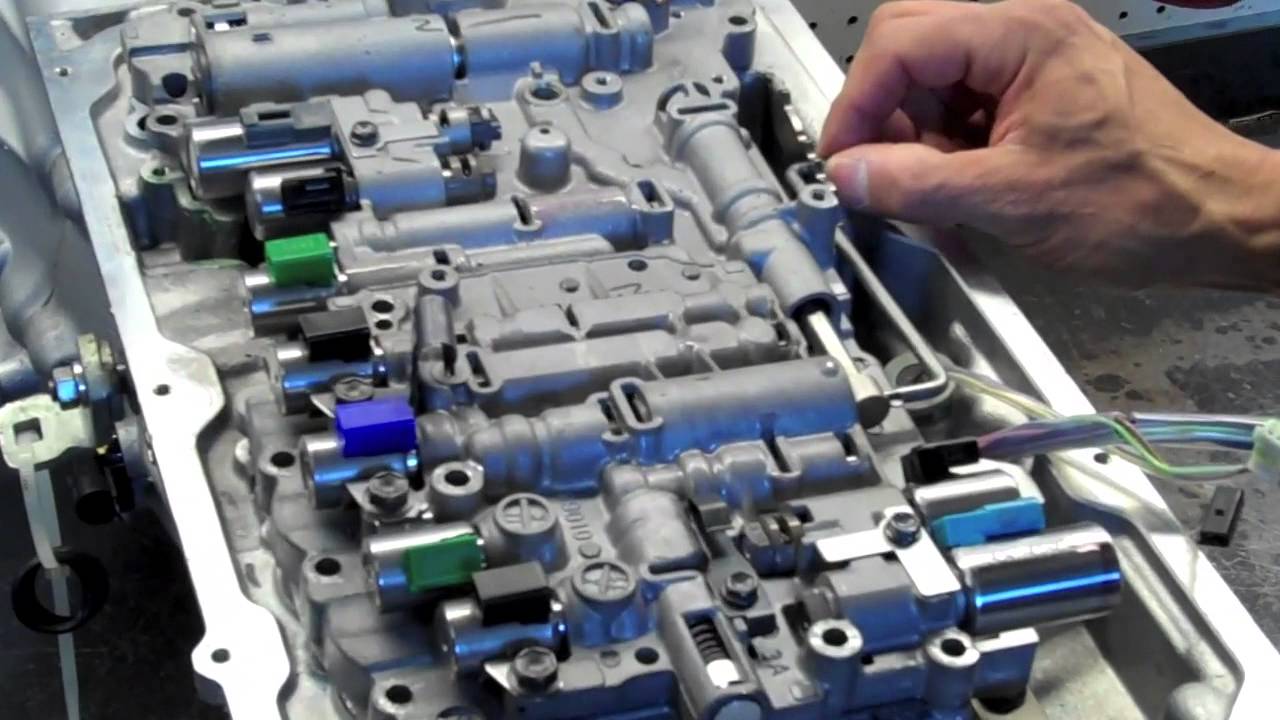

The valve body is the control of the transmission.It could also be called an actuator for the transmission control unit. Inside the valve body, including some solenoids there are many types of valves within it , ranging from regulator valves , switch and servo valves. Checking the hydraulic integrity of the valve body is critical and can be the root cause to many tranmission failures. Our units are completly torn down and hydraulic circuits are checked in several way's spring deflection is also checked. The unit is then updated re-assembled and tested hydraulically & electronically tested using our 1 of 3 valve body data aqusistion test machines.

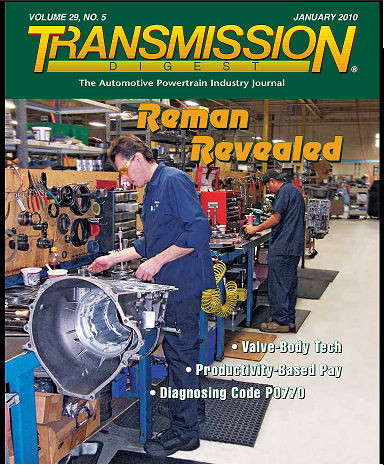

So Solenoids again there are several, from a on-off solenoid to variable bleed & linear, all used in today's automatic transmission. Solenoid operation again is important to the function of the transmission. Solenoids are stripped, Ultra Sonically cleaned, re-assembled then tested on our 1 of 4 test solenoid Data aqusistion test machines. Each test is then stored for future reference. From 2009 Beds Automatic Transmissions have been directly responsable for transmission fixes to the industry and sold worldwide as well as the UK. As featured in Transmission Digest & 911 Porsche world.

Read More

We will use our 40+ years of fault finding experience to resolve your vehicle problems. We are specialists. We have the best trained staff..

We are trained on the latest systems and are equipped to the best standards. We have the best technical resources. We have a vast amount of specific experience.

We agree a budget with you and stick to it. We put you in control of the repair process, your car, your problem, your money, you decide.

The root of all NVH problems is a vibration. In some cases, these are unwanted or unexpected vibrations, and in other cases, they are normal and always present (e.g. engine combustion), but they are noticeably disturbing when transmitted to the passenger compartment. Sound is simply a vibration that is transmitted through the air (or another medium) and is heard when it reaches a person's ear. Although the perfect hearing range is 20 Hz to 20 kHz, most of us are more like 100 Hz to 15 kHz at best. Vibrations are usually felt at frequencies below 200 Hz, and in the overlapping frequency, range vibrations can be both felt and heard.

In order to deal with this frequency range effectively, our NVH kits contain both microphones (for sound), and accelerometers (for vibrations). Traditionally, NVH problems have been viewed as difficult to solve, with NVH complaints being subjective as people have different levels of NVH acceptance or feeling. A technician needs the right tools and procedures to be able to tackle these issues effectively, to diagnose complaints in an objective, repeatable and easy manner. The NVH kit does this, while also generating customer reports to show that an improvement has been made against the customer’s complaint.

Your vehicle problems solved by specialist diagnostics services in Luton. Highly trained Technicians accurately identify vehicle faults and problems. We’ll advise on the necessary repair process. We will confirm the cause and suggest a course of action to solve the problem. You choose what you what to do. You remain in control of the budget. We apply our expertise, our experience, our resources and our skill in equal measure to ensure your problem is resolved in the most cost effective, value for money way

We have a vast inventory of main dealer equipment which includes; Ford IDS & FRDS Mercedes Star and aftermarket equipment such as; Snap-on Zeus, Autologic, Autel. Another piece of equipment used is an first look sensor. The FirstLook Engine Diagnostic Sensor offers a fast and accurate method to diagnose automotive engine problems such as burnt valves, bad injectors and other performance problems without major disassembly of the engine. When connected to the exhaust or vacuum side of the engine to be tested the FirstLook engine diagnostic sensors enables our technicians to quickly display a complete picture of core engine performance on a suitable digital storage lab scope.

Mauris tellus ipsum, tempor elementum tortor sit amet, la cinia mattis leo. Maecenas iaculis dui et eros ullamcorper pulvinar. Pellentesque dapibus, ex quis maximus sollicitudin, lorem est dapibus felis, ut feugiat mauris ante in turpis. Phasellus volutpat in leo ut finibus. Interdum et malesuada fames ac ante ipsum primis in faucibus. Phasellus in nibh aliquam augue ullamcorper feugiat. Aenean consequat tellus ac fringilla gravida. Nulla condimentum ligula nec viverra pretium. Integer bibendum ligula nec

Sed a justo pretium, dignissim eros non, congue felis. Nullam nec orci feugiat, tempor libero eu, elementum urna. Integer sagittis lacinia neque non bibendum. Donec nec dui quis tortor ultricies pellentesque. Vivamus eleifend neque in tortor sodales, ut condimentum felis vestibulum. Maecenas massa justo, porttitor posuere dignissim id, vehicula ut odio. Nullam consectetur est a imperdiet egestas. Aenean varius erat nisl. Nullam tincidunt, lacus in tincidunt ornare, magna dui commodo leo, et dapibus

Our valve body test machines allow running a series of tests checking performance of a malfunctioning Valve Body at various gears and pressure inputs. If put simply, they emulate transmission performance of a driven vehicle. Mackie & the Hydratest teams writes scripts that the Controller reads and then issues commands to the unit itself. By running a used Valve Body through a set of carefully elaborated steps and reading outputs the system makes a graphic that is compared to the one taken from an original new Valve Body of the same model. This comparison makes it possible for ourselves to determine the exact source of the problems - be it a damaged solenoid, a worn-out valve or plunger.

| Merc | 9G | 7G | 722.6 |

|---|---|---|---|

| Ford | DCT 450 | TF 81 | 01P |

| ZF | 9HP | 8HP | 6 HP |

Electrical failure (Open/Short or weak performing): Generally modern solenoids are electrically reliable but we compare the electrical performance against the hydraulic reaction. Contamination from Debris: From our experience this is the number one reason for solenoid failure. It can cause poor flow and slow to respond performance. Worn seating causing a poor seal and failure to fully close. Internal seal failure. Worn valve bore wear, mainly found on a Linear solenoid. Bushing issues: mainly referring to Aisin Linear solenoids.